A grey board defines a material that is thick and paper-based. There is no real definite differentiation that can be used in showing the differences between cardboard and paper other than cardboard is thicker than paper.

In addition, the paperboard also holds specific superior attributes such as the aspect of rigidity and foldability. Using the paperboard ISO standards, it is easier to state that cardboard is typically a piece of paper with its total grammage falling above 250g/m2.

Although paper can be manufactured from fibres such as cotton and hemp, the most popular source is wood pulp. It has been estimated that 35% of trees felled each year contribute to the production of paper, although the majority are taken from sustainable forests where trees are continually replaced. Environmental concerns have seen a huge increase in the use of recycled paper and cardboard in the production of paper. Approximately one ton of wood can be saved if it is replaced by one of recycled newsprint.

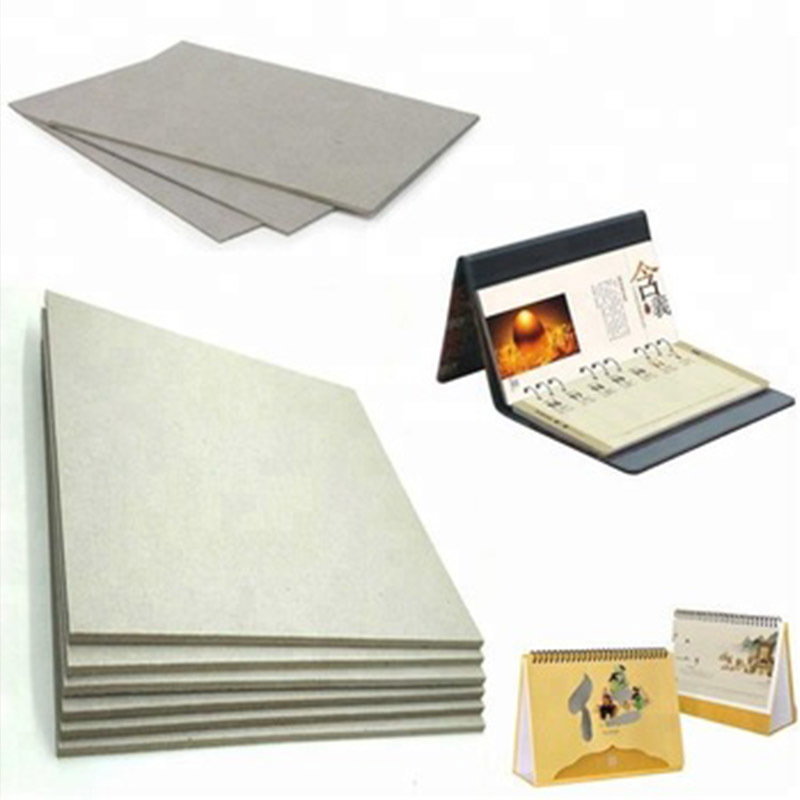

The operating values of the paperboard are that it can be cut and formed with ease, and one of its underlying qualities is that it is strong, which then calls the need of it being used in packaging or quality graphic printing of magazine covers and books. Paperboard can be used in fine arts, where it can be used for drawing or sculptures.

Paperboard dates back to 1817, and this is the year where the first gray paperboard was made in England. Aspects that represented folding cartons first showcased itself around the 1860s, where they were shipped flat to save on the available space, and further from that ease to setup through the customers during times when they were highly required. In 1879, there was the creation of the mechanical die cutting with the availability of creasing of blanks. 1911 saw the issuance of the first Kraft sulphate mill, which was built in the not so big town of Florida. Four years later, there were patent rights provided on the gable top milk carton, and lastly, in 1935 the first ever dairy plant was observed through the use, this is what led to the introduction of the ovenable paper in 1974.

The production of the paperboard is a somewhat significant process, this is due to the fact that it involves that fibrous material being turned to paper, and there is the process where wood is bleached in order to create a layer or more layers on the board. The process that comes up next is optional, where there is the provision for coats that bring out an improved appearance.

Board made from paper has limitless potential, being used daily for packaging a huge variety of goods including food and drinks. Duplex paperboard is also used for stationery, books and creative crafts. As an environmentally friendly, sustainable product, it can be repeatedly used and recycled.

They are both made primarily from recycled paper and hot water. The mixture is then sieved to remove staples and debris then skimmed to remove ink. Occasionally, new wood pulp fibres are added, before being compressed between rollers, dried and wound onto large reels. Depending on the thickness of the layers, the board is either paper or card and can be laminated, lined and printed.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved