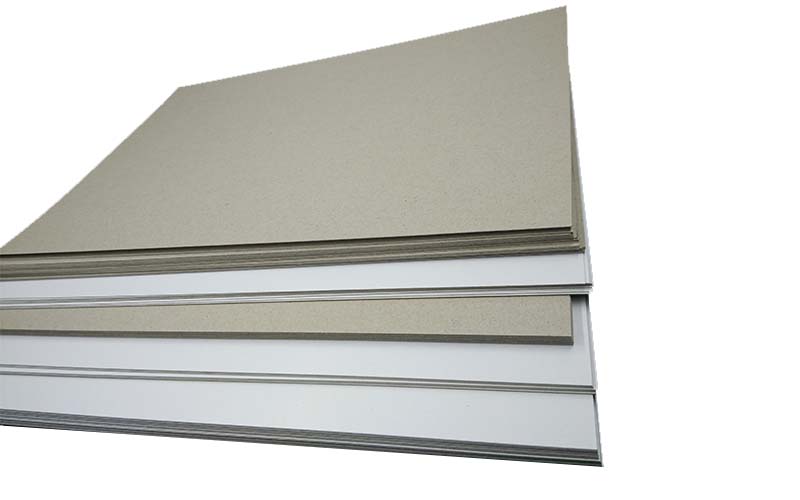

※The coated double-sided cardboard is very suitable for making high-quality products. These boards are coated with high-grade materials, so their surfaces are shiny and dust-proof. It provides high strength and ruggedness. The basic weight is between 230 gsm and 450 gsm. It is used in pharmaceutical, cosmetic, daily necessities, electronic products, and stationery packaging.

※Double-sided cardboard is a cheaper version of the whiteboard. It also provides different textures for printing. Our focus is on product quality, customization, process and service levels.

※These products are widely used and are highly appreciated for their quality and durability. We provide customized solutions to our customers based on their needs.

※We are a double-sided cardboard supplier and offer products in roll and paper form. We offer grey and white double-sided cardboard, which is widely used in the shoe box, cloth box, soap box and toothpaste box packaging. Our wide-width double-sided cardboard is available upon request.

Environmentally friendliness, high stiffness

Stable ink absorption

Technical Specification

Technical Specification

Basis Weight | GSM | 230 | 250 | 300 | 350 | 400 | 450 | 500 |

Weight Range | (gsm) | ±10 | ±10 | ±10 | ±10 | ±10 | ±10 | ±10 |

Thickness | (m/m) | 0.28±0.02 | 0.31±0.02 | 0.37±0.03 | 0.43±0.02 | 0.5±0.02 | 0.56±0.02 | 0.62±0.02 |

Density | (g/cm3) | ≤0.8 | ≤0.8 | ≤0.8 | ≤0.8 | ≤0.8 | ≤0.8 | ≤0.8 |

Moisture | (%) | 5.8±1.0 | 6±1.0 | 6.5±1.0 | 7±1.0 | 7.5±1.0 | 8.0±1.0 | 8.5±1.0 |

Gloss | (%) | 85 | 85 | 85 | 85 | 85 | 85 | 85 |

Brightness and Whiteness | (%) | ≥82 | ≥82 | ≥82 | ≥82 | ≥82 | ≥82 | ≥82 |

Smoothness | (s) | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 | ≥120 |

Coating Weight | (g/m2) | 36 | 35 | 35 | 35 | 35 | 35 | 35 |

Dispersion of Basic Weight at Landscape Orientation | (%) | 6.8 | 7.0 | 7.5 | 8.0 | 8.5 | 9.0 | 9.5 |

Sizing | (g/m2) | 15-20 | 15-20 | 15-20 | 15-20 | 15-20 | 15-20 | 15-20 |

Stiffness Taber(MD) | (mN.m) | ≥2.1 | ≥2.9 | ≥4.1 | ≥6.3 | ≥9.0 | ≥12.1 | ≥15.6 |

Stiffness Taber(CD) | (mN.m) | ≥13.5 | ≥14.5 | ≥17.1 | ≥20.0 | ≥24.8 | ≥30.1 | ≥36.5 |

Folding Endurance | (times) | ≥10 | ≥10 | ≥10 | ≥10 | ≥10 | ≥10 | ≥10 |

Ink absorption Ability | (%) | 18-23 | 18-23 | 18-23 | 18-23 | 18-23 | 18-23 | 18-23 |

Product Details

Product Details

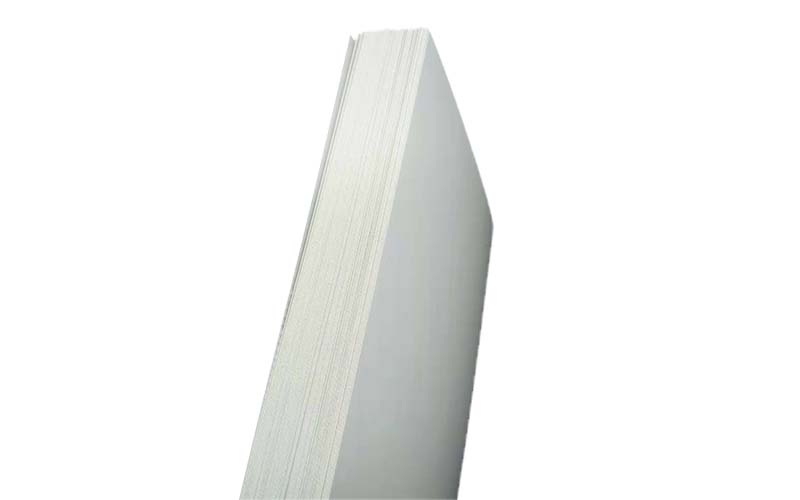

※This product is usually used as a packaging material for small boxes that require high-quality printability.

※We are a supplier of double panels, offering products in the form of rolls and plates. We offer grey and white double panels, which are widely used and available in print areas. We offer single-sided color printing. It can be used as a carton or as a product label.

※Usage: Different boxes, packaging, printing industry. Suitable for high-speed printing of 6~8 colors.

Duplex Board Features

Duplex Board Features

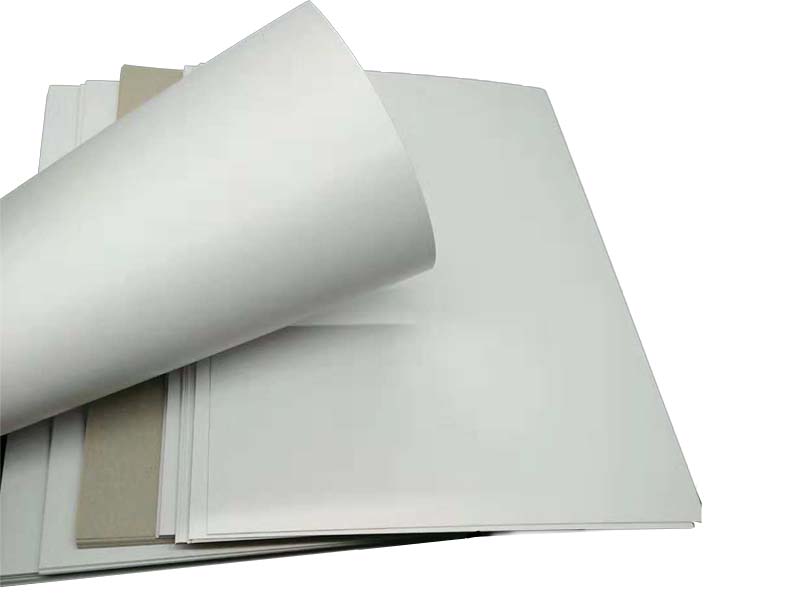

※Environmental protection, high rigidity

※Excellent printing effect and good brightness.

※Good surface smoothness

※Good stiffness and folding

※Stable ink absorption.

Packaging & Shipping

Packaging & Shipping

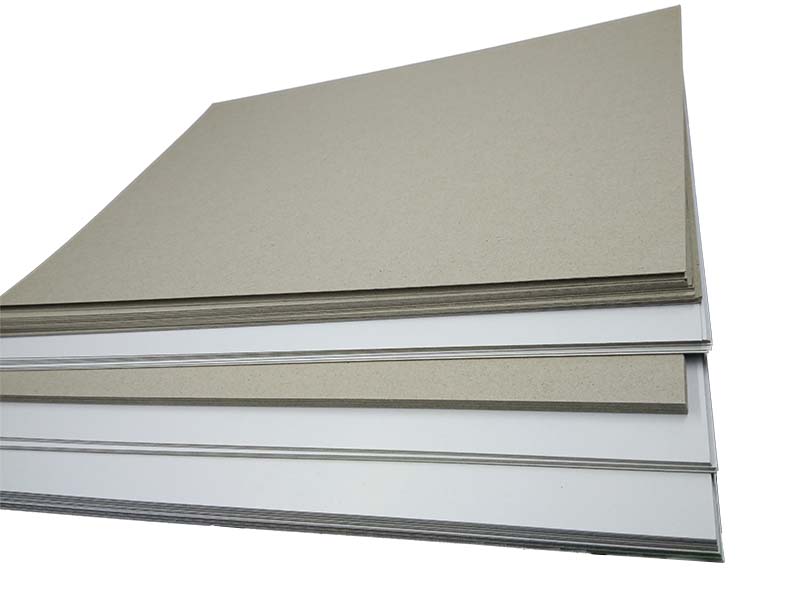

※Packing: reels and plates. Ream packaging is acceptable.

※Standard sheet size: 787x1092mm, 889x1194mm. Minimum size: 900x500mm. Maximum size: 1500x1300mm.

Copyright © 2021 Guangzhou Weyes Network Technology Co., Ltd. | All Rights Reserved